3D Pattern - Prototype Production of 3D Models

FOCAM, under specific circumstances, can harness the benefits of 3D printing for expediting prototype production of models.

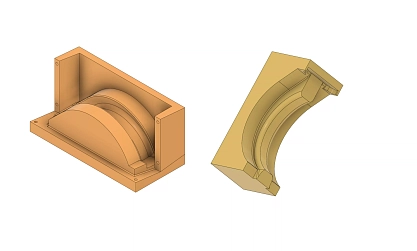

Creation/Modification of 3D Data: A digital model of the future casting is either created or an existing one is modified.

Technology Development: A suitable technology is created and integrated into the 3D data.

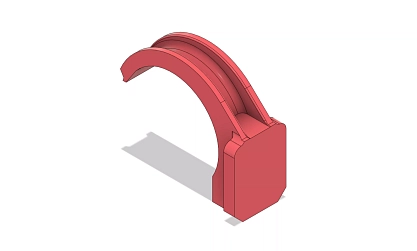

Printing of the 3D Casting Model: The 3D model, along with the technology, is transferred to a 3D printer, which gradually prints the pattern layer by layer.

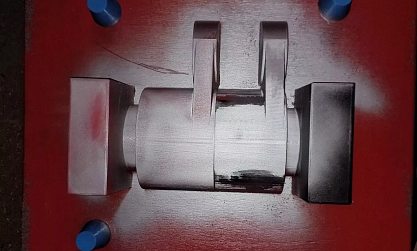

Forming the 3D Model: The printed model serves as the basis for creating the mold, just like traditional models. To increase work productivity, especially for larger series, it's advisable to secure the 3D model onto a plywood board.

3D printing of foundry patterns can be advantageous, for instance, when rapid sampling of castings is necessary. In contrast to traditional methods, where patterns are produced manually or by machining, 3D printing allows for faster and more cost-effective pattern production. This shortens the production time and enables quicker iterations during the prototyping phase.

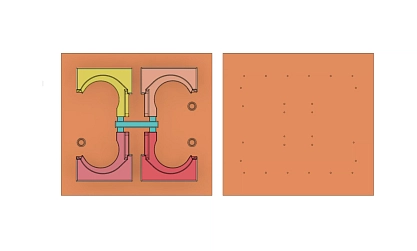

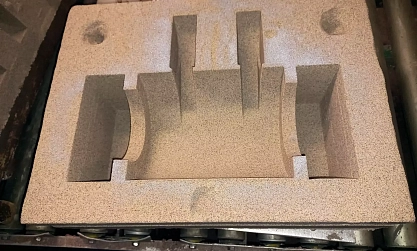

3D Sand Printing

3D sand printing, also known as additive sand manufacturing, enables the production of sand molds and cores for foundry purposes directly from digital CAD data. Once these data are created, it is possible to print the mold or core on a specialized printer. The promise of this technology lies in time savings, greater design freedom for molds and cores, and the avoidance of costly, complex pattern equipment and core boxes, among other benefits. Another suitable application of this technology can be a combination of traditional pattern or pattern equipment molding with 3D printed cores./strong>

FOCAM has several years of experience in casting using 3D printed molds and cores. Based on this expertise, FOCAM is capable of evaluating the suitability of this method and proposing a casting technology.